Volkswagen is making big moves in China, a market where the pace of innovation is nothing short of breathtaking. They’ve just unveiled their new R&D and testing center in Hefei, Anhui province, and it’s not just another facility. This bad boy is the Volkswagen Group’s first comprehensive R&D base outside of Germany, sporting full-process R&D and validation capabilities. It’s also their largest R&D center globally outside their home turf, a clear sign of their serious commitment to the Chinese market.

A Full-Spectrum R&D Ecosystem

This isn’t just about cranking out new models, it’s about building a complete, end-to-end R&D powerhouse right there in China. The new workshops integrate everything from software wizardry to hardware testing and full vehicle validation. For the first time outside Germany, Volkswagen can handle the entire R&D process, compliance approvals, and mass production capabilities for new vehicle platforms and key technologies. This means they can develop and validate vehicles simultaneously from the get-go, shaving significant time off the development cycle.

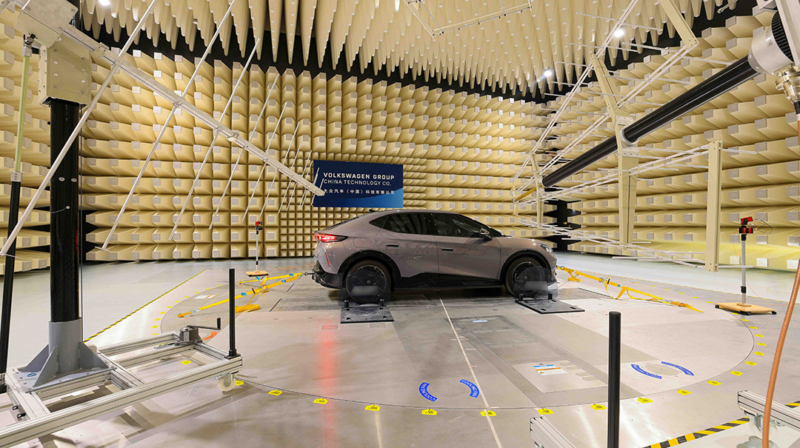

Volkswagen Group China reports that these test workshops are massive, stretching over 100,000 square meters. They’re packed with over a hundred state-of-the-art laboratories, covering crucial areas like software and hardware integration, battery and powertrain testing, and vehicle-level validation. This creates a fully enclosed R&D loop, which Volkswagen expects will trim overall vehicle development time by a hefty 30%. That’s a game-changer when you’re trying to keep up with the lightning-fast evolution of the Chinese EV market.

“In China, for China” on Overdrive

Oliver Blume, the Chairman of the Board of Management for the Volkswagen Group, didn’t mince words, highlighting the accelerated “In China, for China” strategy. He emphasized that the R&D center in Hefei is a comprehensive system designed to support the R&D, testing, and localized production of new-generation intelligent connected vehicles. “This milestone will ensure our local R&D speed becomes more agile, market response more efficient, and more deeply aligned with the core demands of Chinese consumers,” Blume proudly stated. It’s a direct response to a market that demands not just innovation, but rapid innovation, a lesson many global automakers are learning quickly in China.

Ralf Brandstätter, Member of the Board of Management for Volkswagen Group China, further stressed the competitive nature of the Chinese automotive scene. “China is the most competitive automotive market globally, and local customers have extremely high demands for innovation speed and quality. This is precisely why we continue to strengthen our ‘In China, for China’ R&D capabilities,” he explained. By expanding their R&D footprint in Hefei, Volkswagen is sharpening its localized tech development to address Chinese consumer needs with unprecedented speed.

VCTC: Volkswagen’s Innovation Engine

Volkswagen(China) Technology Co., Ltd., or VCTC, kicked off operations in January 2024 and stands as a foundational pillar of this “In China, for China” initiative. It’s the Group’s biggest comprehensive R&D center outside Germany, and uniquely, it’s their only innovation hub exclusively focused on electrification and intelligent connected vehicles. VCTC is bringing together core R&D modules and decision-making for local vehicle and tech projects, working hand-in-hand with joint venture R&D teams. This integrated approach is critical for staying relevant in a market where players like Xpeng and BYD are pushing boundaries almost daily.

A major project at VCTC’s Hefei workshops is the development of the Group’s first Central Computing and Regional Control Electronic/Electrical Architecture (CEA) specifically for the Chinese market. This next-gen CEA is on an aggressive 18-month development cycle, leveraging new Software Defined Vehicle (SDV) processes to potentially cut overall vehicle development time by around 30%. Imagine, a platform that ensures seamless software and hardware integration for everything from intelligent cockpit functions to Advanced Driver-Assistance Systems (ADAS), even enabling vehicle-level OTA updates for upcoming models. We’ve seen how Huawei is getting involved with car brands in China to develop smart systems, so Volkswagen’s move here is spot on.

Beyond speed, localized development and supplier collaboration in the R&D phase could slice new vehicle costs by up to 50% for some key projects. These facilities aren’t just for China either, they’re set to validate core vehicle systems for products and tech headed to overseas markets like ASEAN and the Middle East.

Take the battery and powertrain integration test center, for instance. VCTC engineers can put up to 500 battery systems through their paces annually, scrutinizing performance, lifespan, safety, and how they handle different environments. This extends to electric drive systems, thermal management, and individual battery cells. The platform and module test center boasts advanced gear, including an Electromagnetic Compatibility laboratory for flawless vehicle electronics and a durability test bench that can mimic global road conditions indoors. Coupled with a city test track, Volkswagen has essentially created a closed loop from design to validation in Hefei, syncing up with their global R&D network.

Volkswagen Group isn’t stopping there, they’re already eyeing further expansions for VCTC. A Functional Integration Test (FIT) laboratory is set to go live by mid-2026. This will be one of only two such facilities globally capable of simulating incredibly complex extreme environments. If you’re interested in how other companies are pushing battery tech, check out how BYD is soaring past 113 GWh in battery production, or delve into the world of China’s new battery ID platform which aims to standardize data for global markets.