Volkswagen just made a massive statement in the world’s hottest EV market. The company has officially opened its first-ever comprehensive R&D and testing center outside of Germany, right in the heart of China’s auto industry in Hefei. This isn’t just a new building; it’s a declaration of intent. VW is doubling down on its “In China, for China” strategy, aiming to design, develop, and validate cars locally to keep pace with the lightning-fast Chinese market.

This new facility, Volkswagen (China) Technology Co., Ltd. (VCTC), is now the Group’s largest and most advanced R&D base outside of its German headquarters. It gives VW the power to handle the entire vehicle development process within China, a first for the brand on foreign soil.

A Complete R&D Powerhouse

Stretching across 100,000 square meters, the new workshops house over a hundred advanced laboratories. These facilities create a closed-loop system for development, covering everything from software and hardware integration to battery testing and full-vehicle validation. The biggest win from this setup? Volkswagen expects to slash overall vehicle development time by a staggering 30%. In a market where new models and features appear constantly, that speed is more than an advantage, it’s a survival mechanism.

More Than Just a Slogan

Oliver Blume, Chairman of Volkswagen Group, emphasized that the “In China, for China” strategy is picking up speed. “At our R&D centre in Hefei, China, we have fully established a comprehensive system to support the R&D, testing, and localised production of new-generation intelligent connected vehicles,” he said. The goal is to become more agile and deliver products that truly resonate with Chinese drivers.

Ralf Brandstätter, Volkswagen’s chief for China, was even more direct about the competitive pressure. “China is the most competitive automotive market globally, and local customers have extremely high demands for innovation speed and quality,” Brandstätter noted. To keep up with local players like BYD and Nio, VW knows it has to innovate at local speed. This center is the engine designed to do just that.

The Secret Sauce to Faster, Cheaper EVs

A key project at the Hefei center is the development of Volkswagen’s first China-specific electronic architecture, known as CEA. Think of it as the car’s central nervous system, unifying software and hardware control into a single platform. This is a huge leap forward from traditional, decentralized systems and is critical for creating modern, software-defined vehicles (SDVs).

This architecture is being developed on an aggressive 18-month cycle. It’s what enables the 30% reduction in development time and allows for seamless integration of features like advanced driver-assistance systems (ADAS), intelligent cockpits, and vehicle-level OTA updates. Just as important, by developing technologies and sourcing parts locally from the get-go, Volkswagen anticipates cost reductions of up to 50% for some key projects. This strategy is already bearing fruit, with models like the ID.Unyx 07, developed with Xpeng, going from concept to near-production in record time. It also paves the way for future models like the ID. Era EREV crossover.

Built to Last: Rigorous Testing for a Demanding Market

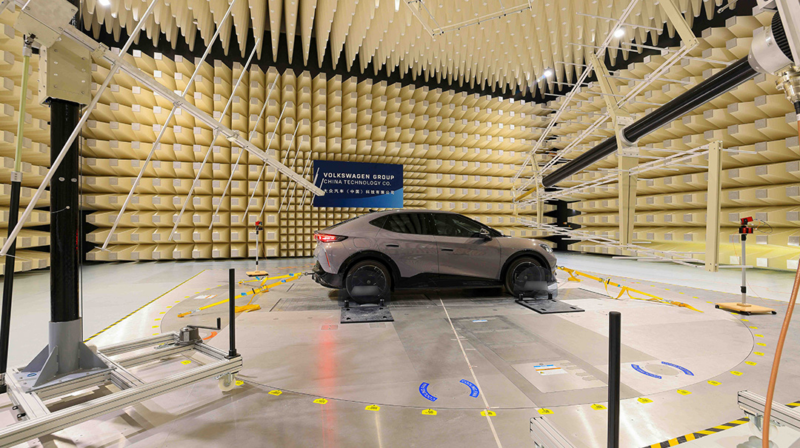

The Hefei center is equipped with some seriously impressive testing gear. The battery and powertrain integration lab can put up to 500 battery systems through their paces annually, testing for performance, safety, and durability under all conditions. Meanwhile, an Electromagnetic Compatibility (EMC) laboratory ensures that the dozens of electronic systems in a modern car don’t interfere with each other or with your smartphone.

A vehicle durability test bench can simulate the world’s toughest road conditions without ever leaving the building. Combined with a dedicated city test track, Volkswagen has created a complete validation loop in Hefei. This ensures that vehicles are not only developed quickly but are also built to withstand the rigors of daily use, whether in China or in export markets across the globe.

Looking ahead, VW plans to expand its capabilities even further. A Functional Integration Test (FIT) laboratory, one of only two in the world capable of simulating complex extreme environments, is set to open by mid-2026. It’s clear Volkswagen isn’t just adapting to the Chinese market, it’s building its future there.