Xpeng’s subsidiary, Aridge, just rolled out the first “Land Carrier” modular flying car from its Guangzhou facility in Huangpu District. This marks a pivotal moment, as it’s essentially the world’s first mass-production line for flying cars taking flight. The company says this initial aircraft starts experimental test flights soon, aiming to fine-tune performance and manufacturing processes before full-scale deliveries kick off next year.

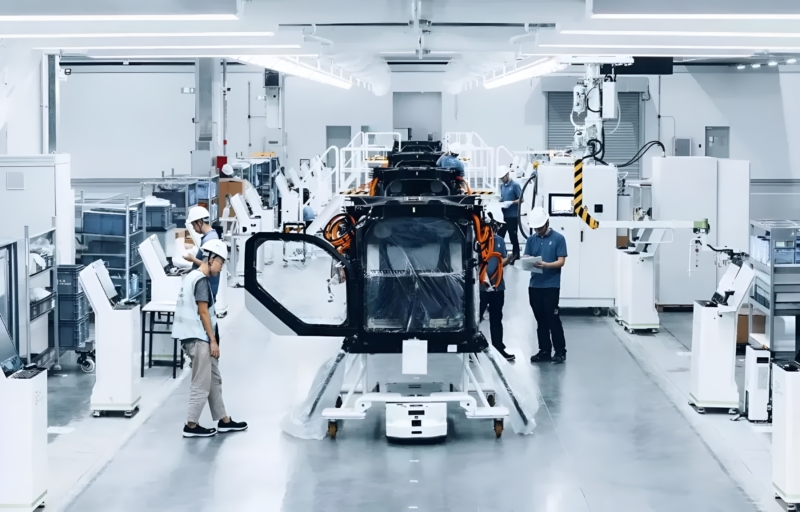

A Factory Like No Other

This isn’t your typical auto plant. Spanning roughly 120,000 square meters, the facility is purpose-built to churn out Xpeng’s innovative modular flying car. It is a vehicle that ingeniously separates into a ground-based “mother vehicle” and an aerial module. The ground unit is a beefy one, featuring a three-axle, six-wheel setup with all-wheel drive and rear-wheel steering. This combo provides both serious load capacity and off-road chops. Measuring about 5.5 meters long, 2 meters wide, and 2 meters high, it is designed to slip into standard parking spots and only requires a conventional driver’s license to operate.

Now, for the really exciting part: the aerial module. It is a sleek, electric, six-rotor design with dual ducts. Its carbon fiber fuselage and rotor blades strike a perfect balance between strength and minimal weight. And for those lucky enough to take to the skies, a 270-degree panoramic cockpit promises an expansive view that will redefine your commute.

Precision Engineering in Five Workshops

The factory itself is a marvel, boasting five core workshops: composites, propulsion, assembly, painting, and final integration. The composites workshop is a powerhouse, set to produce 300 tons of carbon fiber components yearly, including arms, rotor blades, and floor panels. This makes it one of the largest aviation carbon fiber component facilities globally. The propulsion workshop handles the intricate assembly and testing of lift and flight control units. It uses an integrated assembly and testing line for electric drives and rotors, ensuring meticulous quality control with automated traceability for every component. It is a testament to the advanced manufacturing capabilities emerging from China, pushing boundaries similar to developments seen in other EV sectors, such as those discussed in the context of SAIC’s solid state battery plans.

Assembly relies on cold-connection techniques like riveting and adhesive bonding for fuselage components, a detail that speaks to the precise engineering involved. The painting workshop is no less advanced, employing an “8C6B” multi-layer spraying process on a flexible, high-automation line. In the final assembly stage, nine major systems are integrated and rigorously tested to meet stringent design and airworthiness standards. A cloud based calibration system even automates tests for autonomous driving, flight control, and center of gravity measurements, ensuring every “Land Carrier” is ready for action. This reflects a growing trend in complex manufacturing in China, which also informs advancements in conventional EVs and their components, including those like the standardization of EV battery data.

Flying High with Intelligent Control

The “Land Carrier” isn’t just about getting off the ground. It offers both manual and autonomous flight modes. If you fancy a bit of hands-on action, a single stick system allows for effortless one-handed control. For those who prefer to let the machine do the work, the autonomous mode is packed with intelligent route planning, automated flight along preset paths, and one button takeoff and return. It also features 3D composite vision and landing assistance, taking the stress out of navigating the skies. The focus on advanced autonomous capabilities here is very much in line with other cutting-edge developments in the Chinese EV market, such as Volkswagen and Xpeng’s collaboration on autonomous driving.

This factory is also a champion of sustainability, operating on a “refined, intelligent, green” principle. It uses photovoltaic power, energy efficient equipment, and a digital energy management system to keep carbon emissions to a minimum. At full tilt, the plant aims to produce an impressive 10,000 units annually. Currently, it starts with an initial capacity of 5,000, with one aircraft rolling off the line every 30 minutes. The pace of innovation and production in China’s EV and related sectors remains incredibly rapid, a characteristic that defines the broader automotive market, much like the swift evolution seen in companies like BYD, as well as the dynamic changes discussed in this article about the country’s EV sales race.